Best-In-Class Medical Device Quality & Manufacturing meets Best-In-Class Automotive Cost Savings

Our expertise in Kaizen Principles brings lean strategies to Medical Device. These principles allow us to bring better medical devices to market faster and at lower costs than other manufacturers.

Capabilities

True One-Stop-ShopFrom Early Stage Design Through Commercialization

Engineering

Expert design and engineering services that turn concepts into optimized medical devices through rapid prototyping, testing, and manufacturable solutions.

Learn More

Manufacturing

From FDA‑registered production and clean‑room assembly to final packaging and sterilization, Trident ensures compliance, quality, and competitive cost.

Learn More

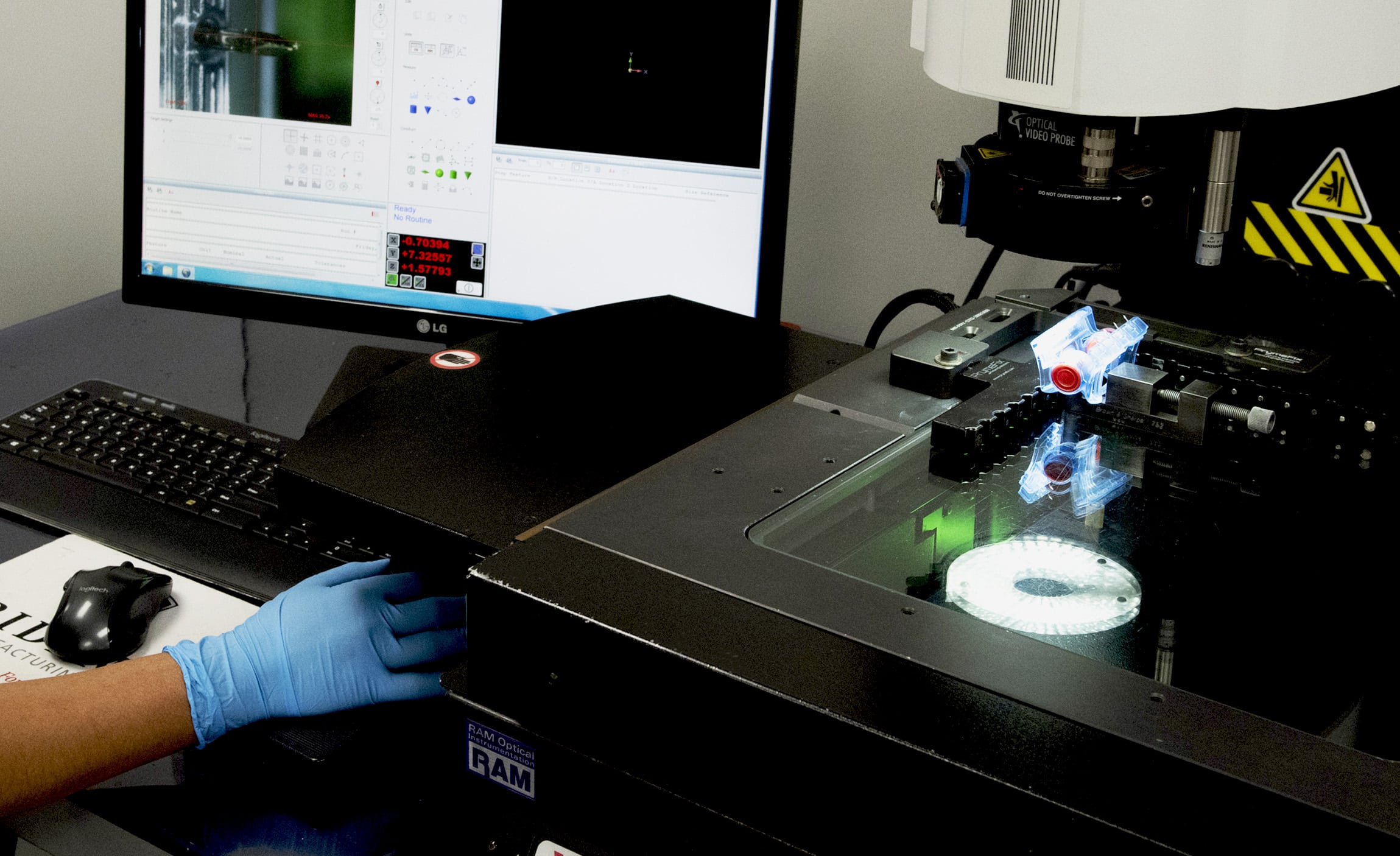

Quality

ISO‑13485 certified and FDA‑registered, Trident delivers traceable, fully tested medical devices with zero‑defect standards from start to finish.

Learn More

Capabilities

Comprehensive capabilities from design and prototyping to clean‑room assembly, packaging, and sterilization, providing a single-source medical device partner.

Learn More

“Delivering perfect quality and flawless execution are a pre-requisite at Trident. The only question is how to eliminate waste from the entire process to deliver the best product at the best price.”

John SapienteCEO Trident Manufacturing